What is a winch?

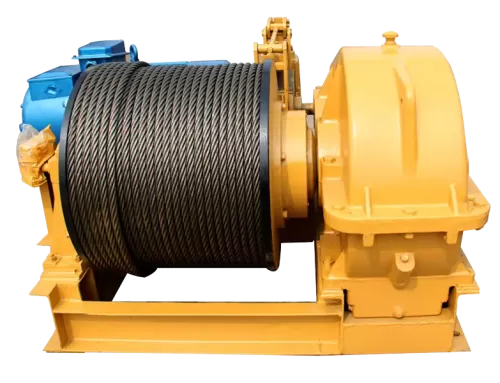

A winch is a mechanical device designed to wind in or let out a rope, cable, or chain, enabling the pulling or lifting of heavy loads. At its core, it consists of a spool (also known as a drum) around which the line is wound, and a crank or motor that turns the spool. This simple yet effective mechanism has been instrumental in various applications, from maritime operations to off-road vehicle recoveries.

Anatomy of a Winch

Understanding the essential components of a winch can shed light on its functionality:

-

Drum (Spool): The cylindrical component where the cable or rope is wound.

-

Motor or Crank: Provides the necessary force to turn the drum.

-

Gear Train: A set of gears that amplifies the motor’s power, enabling the winch to handle heavier loads.

-

Brake System: Prevents the load from unwinding unintentionally.

-

Fairlead: Guides the cable onto the drum evenly, reducing wear and tear.

Types of Winches and Their Applications

Winches come in various types, each tailored to specific tasks and environments:

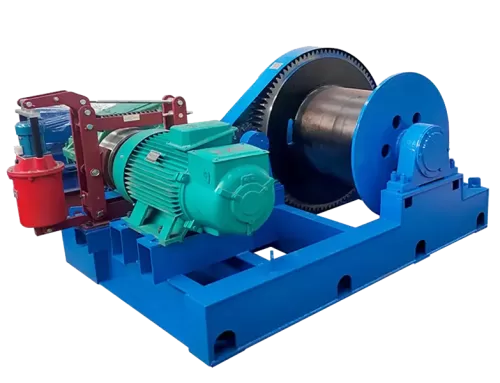

Electric Winches

Powered by an electric motor, these winches are popular for their ease of use and reliability. They’re commonly found on off-road vehicles and trailers, providing a convenient solution for vehicle recovery and load securing.

Hydraulic Winches

Utilizing a vehicle’s power steering pump or a dedicated hydraulic system, hydraulic winches offer consistent performance and can operate for extended periods without overheating. They’re often employed in industrial settings and heavy-duty towing operations.

Manual Winches

Also known as hand winches, these are operated by turning a crank by hand. While they require physical effort, manual winches are invaluable when power sources are unavailable, such as in remote locations or for small-scale applications.

Air (Pneumatic) Winches

Powered by compressed air, these winches are ideal in environments where electrical sparks could pose a hazard, like in mining or offshore drilling operations. They offer a safe and reliable means of lifting or pulling in explosive atmospheres.

Capstan Winches

Featuring a vertical drum, capstan winches are designed for tasks requiring the line to be released at various angles. They’re commonly used in marine applications and theater stage rigging.

Frequently Asked Questions (FAQs)

Q: Can I install a winch on any vehicle?

A: While many vehicles can accommodate a winch, it’s essential to ensure that your vehicle’s frame and electrical system can support the winch’s weight and power requirements.

Q: How do I maintain my winch?

A: Regular maintenance includes cleaning the winch after use, inspecting the cable for frays, lubricating moving parts, and checking electrical connections.

Q: Is a synthetic rope better than a steel cable?

A: Both have pros and cons. Synthetic ropes are lighter and safer if they break, but they’re more susceptible to abrasion and UV damage. Steel cables are more durable but can be hazardous if they snap under tension.

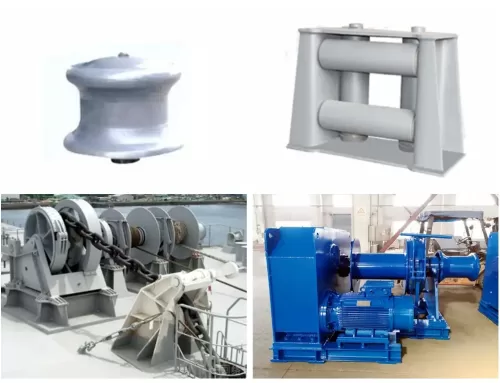

As a professional Industrial & Marine Winch Supplier, GT Winch offers

- Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

- High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

- Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

- General winches,marine winches,construction winches.etc available.Welcome to send a free inquiry.

OEM Supported

Email: info@gtwinch.com

-

Type of Winch-General Winch, Marine Winch, Mine Winch, or Other Type

-

Load Capacity-What is the maximum load (in tons or kilograms) the winch needs to handle?

-

Rope / Cable Type-What type of rope or cable will be used? (e.g., steel, synthetic)

-

Power Source-What type of power is required? (e.g., electric, hydraulic, pneumatic, manual)