Top 5 Industrial Applications for Electric Winches

Hey there! I’m John, a senior engineer at GT Winch Group. Over the past decade, I’ve helped hundreds of clients—from shipyard managers to mining operators—pick the perfect electric winch, hydraulic winch, or diesel winch for their needs. Let me save you time (and headaches) with plain-talk advice you won’t find in technical manuals.

Step 1: Know Your Load (It’s Not Just About Weight!)

“But My Supplier Said 20 Tons Is Enough!”

Hold on! Load capacity isn’t just the number on the spec sheet. Ask:

- Is the load stable or swinging? (Swinging loads = 25% more stress!)

- How often will you lift? (10 lifts/day vs. 100? Durability matters!)

- Real-World Example:

A construction team in Norway bought a “50-ton winch” but kept burning out motors. Why? Their steel beams swung violently in coastal winds. We upgraded them to a 65-ton hydraulic winch with stabilizers—problem solved.

Step 2: Electric, Hydraulic, or Diesel? Let’s Break It Down

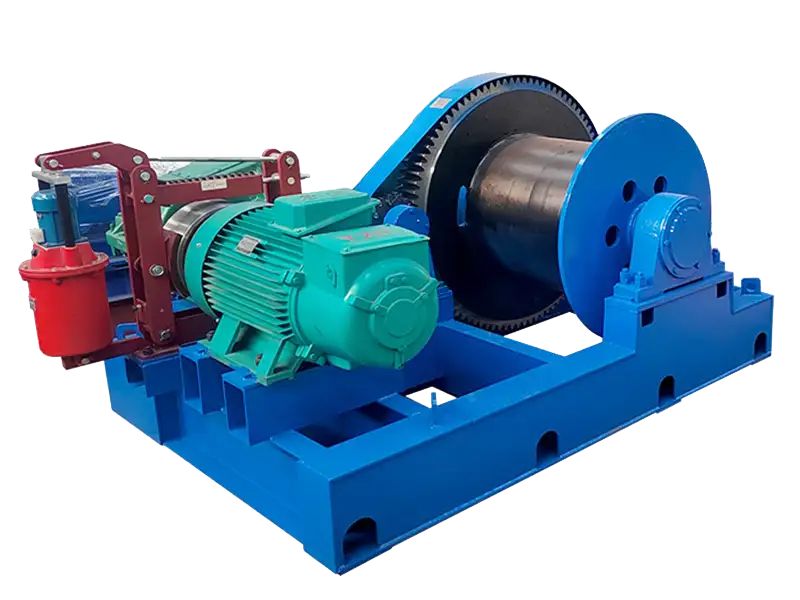

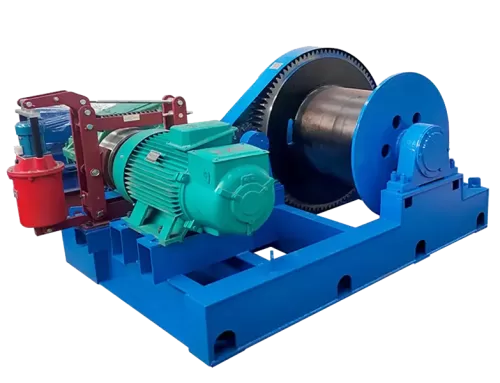

Electric Winches – The “Easy Button”

- Best for: Factories, warehouses, solar farms.

- Pros: Quiet, eco-friendly, plug-and-play.

- Cons: Struggles with continuous heavy lifting (motors overheat).

Hydraulic Winches – The Muscle

- Best for: Mining, offshore rigs, bridge construction.

- Pros: Handles 500+ tons, works in explosions zones (no sparks!).

- Cons: Needs a hydraulic pump—bulky and pricier.

Diesel Winches – The Off-Grid Hero

- Best for: Remote sites with no electricity.

- Pros: Raw power anywhere.

- Cons: Loud, smoky, and higher fuel costs.

My Rule of Thumb:

- Under 50 tons & indoors? → Electric.

- Over 100 tons or outdoors? → Hydraulic.

- Middle of nowhere? → Diesel.

Step 3: Don’t Ignore the “Boring Stuff” (Trust Me!)

Step 4: Test Before You Buy (Yes, Really!)

Most suppliers (including us!) offer on-site demos. Here’s what to check:

- Noise levels: Can your team work nearby without ear protection?

- Control responsiveness: Delayed reactions = danger.

- Real-World Test:

A port in Singapore tested 3 winches under monsoon rains. Ours won because the waterproof controls worked flawlessly.

FAQs About How to Choose Industrial Winch

Q: Can I use one winch for multiple jobs?

A: Yes, but don’t push it. A winch designed for smooth factory lifts might fail in a dusty mine. Customize if your needs vary!

Q: How do I maintain a winch?

A: Simple! Monthly grease for cables, annual motor checks, and always replace worn parts ASAP. We provide free checklists!

Q: Do you accept OEM for industrial winch equipment?

A: Yes of course we do.

Need a Winch Tailored to YOUR Industry?

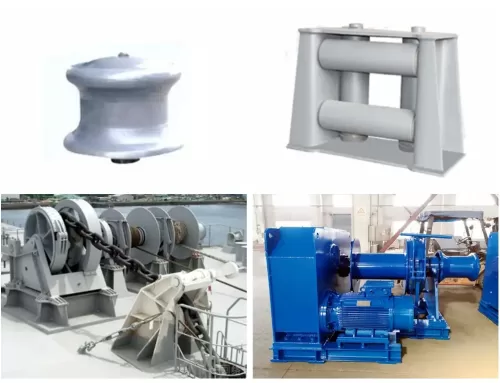

At GT Winch Group, we’ve built custom hydraulic and electric winches for:

- Ports lifting cargo containers

- Mines hauling ore carts

- Shipyards deploying anchors

Talk to Our Winch Experts!

📧 Email: info@gtwinch.com

📱 WhatsApp: +86 13353666378

🌐 Visit: www.gtwinch.com

As a professional Industrial & Marine Winch Supplier, GT Winch offers

- Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

- High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

- Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

- General winches,marine winches,construction winches.etc available.Welcome to send a free inquiry.

OEM Supported

Email: info@gtwinch.com

-

Type of Winch-General Winch, Marine Winch, Mine Winch, or Other Type

-

Load Capacity-What is the maximum load (in tons or kilograms) the winch needs to handle?

-

Rope / Cable Type-What type of rope or cable will be used? (e.g., steel, synthetic)

-

Power Source-What type of power is required? (e.g., electric, hydraulic, pneumatic, manual)