Electric Winches

Cabrestante eléctricoElectric Winches

Electric winch meets various needs of many winch markets. It has wide applications. Users can choose to use the winch separately or they can choose to make use of winch equipment together with lifting equipment, or other mechanical parts.

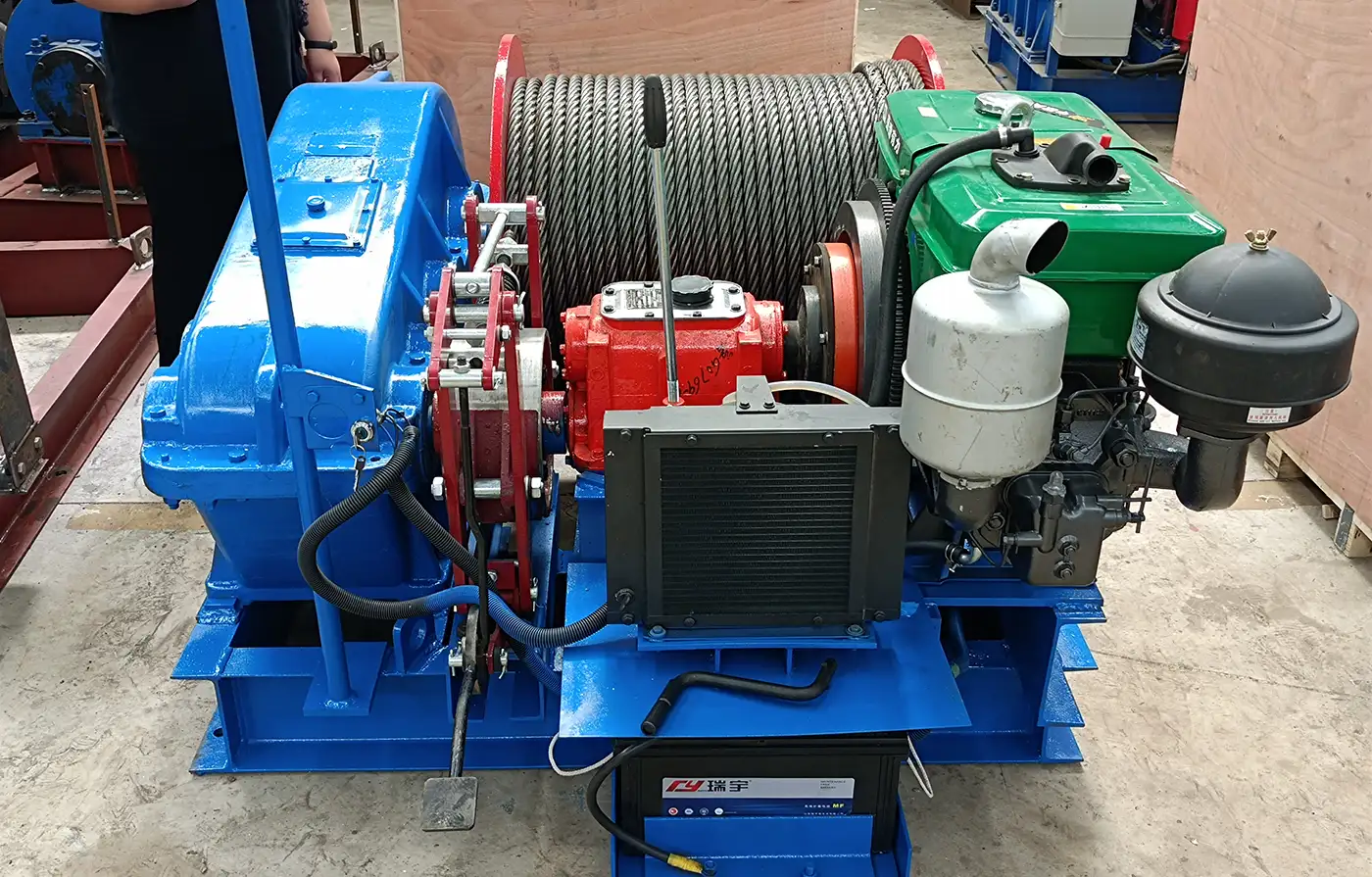

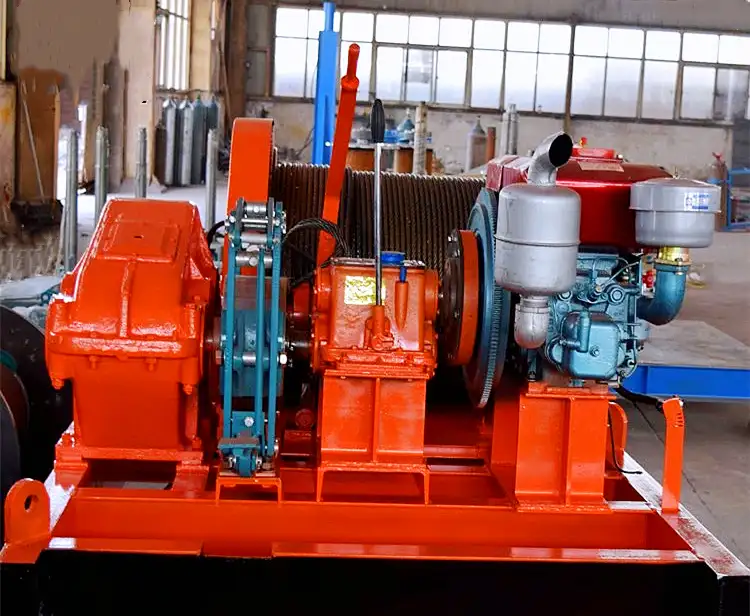

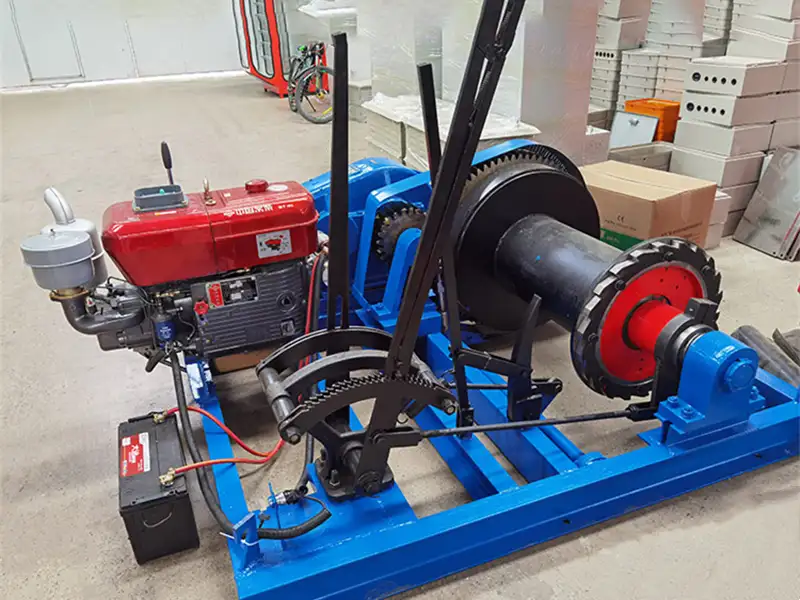

Diesel Winches

Cabrestantes diéselDiesel Winches

Diesel engine winches are mainly used for power transmission engineering (including underground power cable engineering), telecommunication, building tower erection, pulling cables, pulling wires, and lifting heavy objects.Hydraulic Winches

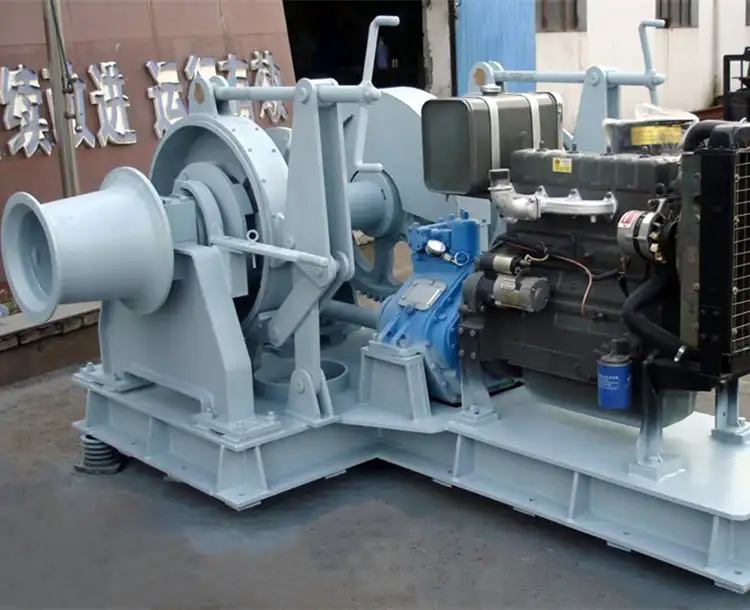

Cabrestante hidráulicoHydraulic Winch Manufacturer

A hydraulic winch is mainly composed of a hydraulic motor, multi-disc brake, planetary gearbox, clutch, reel, shaft, frame, rope press, etc. It is widely used in shipbuilding, railway, metallurgy marine engineering, construction, docks, mines, etc.

Other Optional Winch Accessories:

Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

General winches,marine winches,construction winches.etc available.Welcome to send a free inquiry.

1. Information Needed for a Diesel Winch Inquiry

When inquiring about a diesel engine-powered winch, please provide the following details:

- Load capacity (How much weight the winch needs to handle).

- Rope drum capacity (Length and number of ropes required in meters).

- Preferred winch model (If you have one in mind).

- Speed requirement (Lifting or pulling speed in meters per minute).

- Winch working sketch (If available, this will help us better understand your needs).

2. Load Test Standards for Winches

- Dynamic load test: Performed at 1.1 times the rated load capacity.

- Static load test: Performed at 1.25 times the rated load capacity.

3. Maintenance Tips

- Lubrication: Regular lubrication is essential for smooth operation and longer service life.

- Steel wire rope: Inspect for broken wires, damaged strands, or excessive wear. Replace immediately if it reaches scrapping standards.

- Pulley block: Check for wear on the rope groove, cracks in the flange, and ensure the pulley moves freely.

- Brakes: Inspect daily. Ensure proper function, no sticking, and correct fitting of brake shoes to the brake wheel.

OEM Supported

Email: info@gtwinch.com

-

Type of Winch-General Winch, Marine Winch, Mine Winch, or Other Type

-

Load Capacity-What is the maximum load (in tons or kilograms) the winch needs to handle?

-

Rope / Cable Type-What type of rope or cable will be used? (e.g., steel, synthetic)

-

Power Source-What type of power is required? (e.g., electric, hydraulic, pneumatic, manual)