Ensuring Safety: Best Practices for Operating Mooring Winches

Mooring winches are critical equipment used in maritime operations to secure ships to docks or anchor points. Ensuring safe operation of these winches is essential for the safety of the crew, vessel, and the surrounding environment. In this article, we will explore the different types of mooring winches, how they work, and most importantly, the best practices and safety procedures you should follow to operate them safely.

Types of Anchor Winches

Mooring winches come in various designs to accommodate different operational requirements. Below are the main types of mooring winches used in the maritime industry:

1. Mechanical Mooring Winches

Mechanical mooring winches are powered by manual cranks or hydraulic systems. These winches are commonly used in smaller vessels and are ideal for simpler mooring operations.

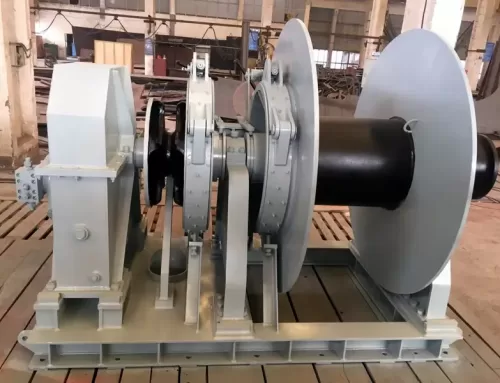

2. Hydraulic Mooring Winches

Hydraulic mooring winches are powered by hydraulic systems that provide high power for heavy-duty operations. They are commonly used on larger vessels and are known for their reliability and efficiency in securing ships.

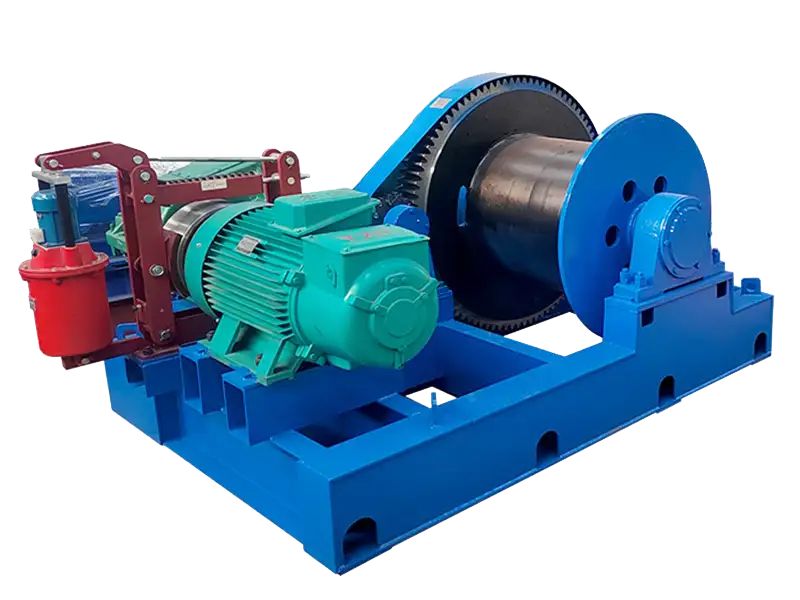

3. Electric Mooring Winches

Electric mooring winches operate with electric motors. They are more energy-efficient compared to hydraulic winches and are often used in vessels where space and power supply are concerns.

4. Pneumatic Mooring Winches

Pneumatic mooring winches use compressed air to operate. They are often used in areas with specific safety requirements, as they do not generate heat or sparks during operation.

Each type of winch is designed to handle different tasks, but the principles of safe operation remain the same across all models.

Best Practices for Mooring Winch Safety

1. Regular Inspection and Maintenance

Before each operation, it is crucial to inspect the mooring winch thoroughly. Check for any signs of wear and tear, such as frayed ropes, loose components, or hydraulic leaks. Regular maintenance, including cleaning and lubrication of moving parts, can help prevent malfunctions and ensure smooth operation.

2. Proper Training for Operators

Operators should undergo proper training to understand the operation of the mooring winch, including how to use the control systems, apply correct tension, and handle emergency situations. Ensure all operators are familiar with the mooring winch safety procedures and emergency protocols.

3. Use of Personal Protective Equipment (PPE)

Operators must always wear the necessary PPE, including gloves, helmets, and safety footwear, to prevent injuries from accidental rope snaps or other hazards associated with winch operation.

4. Monitor Environmental Conditions

Always consider environmental factors such as wind, sea state, and visibility before using the mooring winch. In adverse conditions, extra caution should be taken, and additional assistance may be needed.

5. Use the Right Type of Winch for the Job

Choosing the appropriate winch for your specific needs is vital. Whether you are using a general winch, marine winch, or mine winch, ensure the winch is suitable for the size and weight of the vessel or load. Using the wrong type of winch can lead to overloading and increased risk of failure.

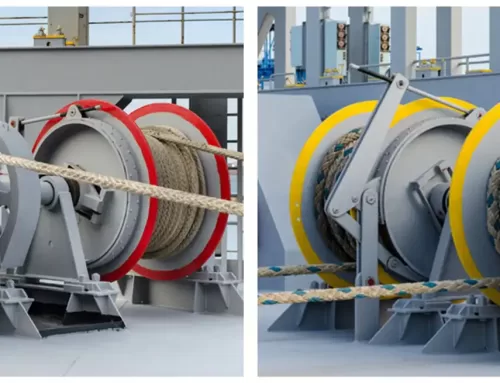

GT Winch Group: Your Reliable Partner for Quality Mooring Winches

GT Winch Group is a professional manufacturer of high-quality mooring winches and winch components. With years of experience in producing durable and reliable winches, our products are widely used across industries such as maritime, construction, and mining. We offer OEM services and customize winches according to your specifications.

Our heavy-duty marine winches, general winches, and mine winches are designed to meet the rigorous demands of various industrial applications. Visit our factory and send a free inquiry to discover how we can provide you with the best winch solutions at competitive prices.

Winch Specifications Table

| Feature | General Winch | Marine Winch | Mine Winch |

|---|---|---|---|

| Load Capacity | Up to 150 tons | Up to 500 tons | Up to 200 tons |

| Motor Type | Electric, Diesel, Hydraulic | Electric, Diesel, Hydraulic | Electric, Diesel, Hydraulic |

| Drum Size | Customized | Customized | Customized |

| Rope Type | Steel Cable, Synthetic | Steel Cable, Synthetic | Steel Cable |

| Application | General Industry | Maritime Operations | Mining Operations |

| Safety Features | Overload Protection | Emergency Stop | Automatic Braking |

| Customization | Available | Available | Available |

Ready to Upgrade Your Vessel’s Mooring System?

With GT Winch Group’s expertise and premium anchor winches, you’ll enjoy unmatched reliability and safety. From installation guidance to after-sales support, we’re here to ensure smooth sailing.

Need a Winch Tailored to YOUR Industry?

At GT Winch Group, we’ve built custom hydraulic and electric winches for:

- Ports lifting cargo containers

- Mines hauling ore carts

- Shipyards deploying anchors

Talk to Our Winch Experts!

📧 Email: info@gtwinch.com

📱 WhatsApp: +86 13353666378

🌐 Visit: www.gtwinch.com

As a professional Industrial & Marine Winch Supplier, GT Winch offers

- Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

- High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

- Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

- General winches,marine winches,construction winches.etc available.Welcome to send a free inquiry.

OEM Supported

Email: info@gtwinch.com

-

Type of Winch-General Winch, Marine Winch, Mine Winch, or Other Type

-

Load Capacity-What is the maximum load (in tons or kilograms) the winch needs to handle?

-

Rope / Cable Type-What type of rope or cable will be used? (e.g., steel, synthetic)

-

Power Source-What type of power is required? (e.g., electric, hydraulic, pneumatic, manual)